On selective laser melting of Inconel 718: Densification, surface roughness, and residual stresses - ScienceDirect

Schematics of additive manufacturing (AM) by selective laser melting... | Download Scientific Diagram

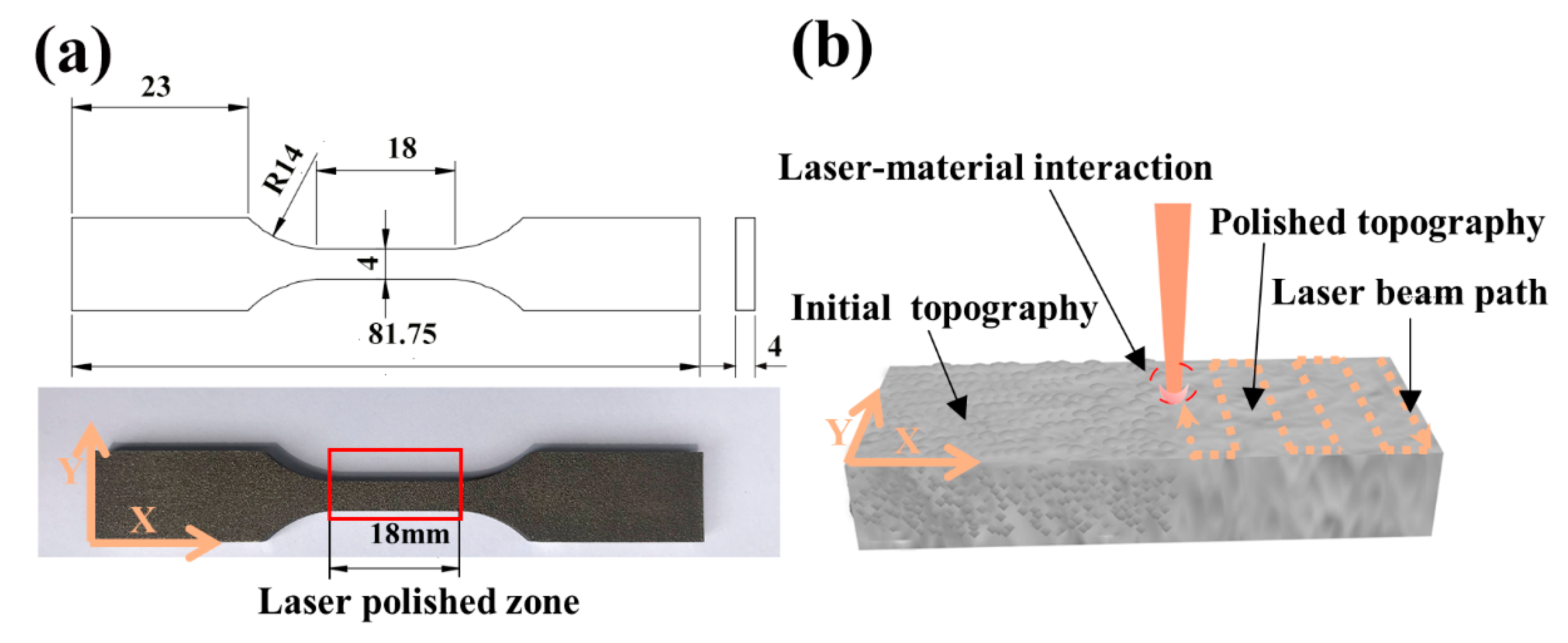

Crystals | Free Full-Text | Study on Surface Roughness Improvement of Selective Laser Melted Ti6Al4V Alloy

Metals | Free Full-Text | Process Optimization for Up-Facing Surface Finish of AlSi10Mg Alloy Produced by Laser Powder Bed Fusion

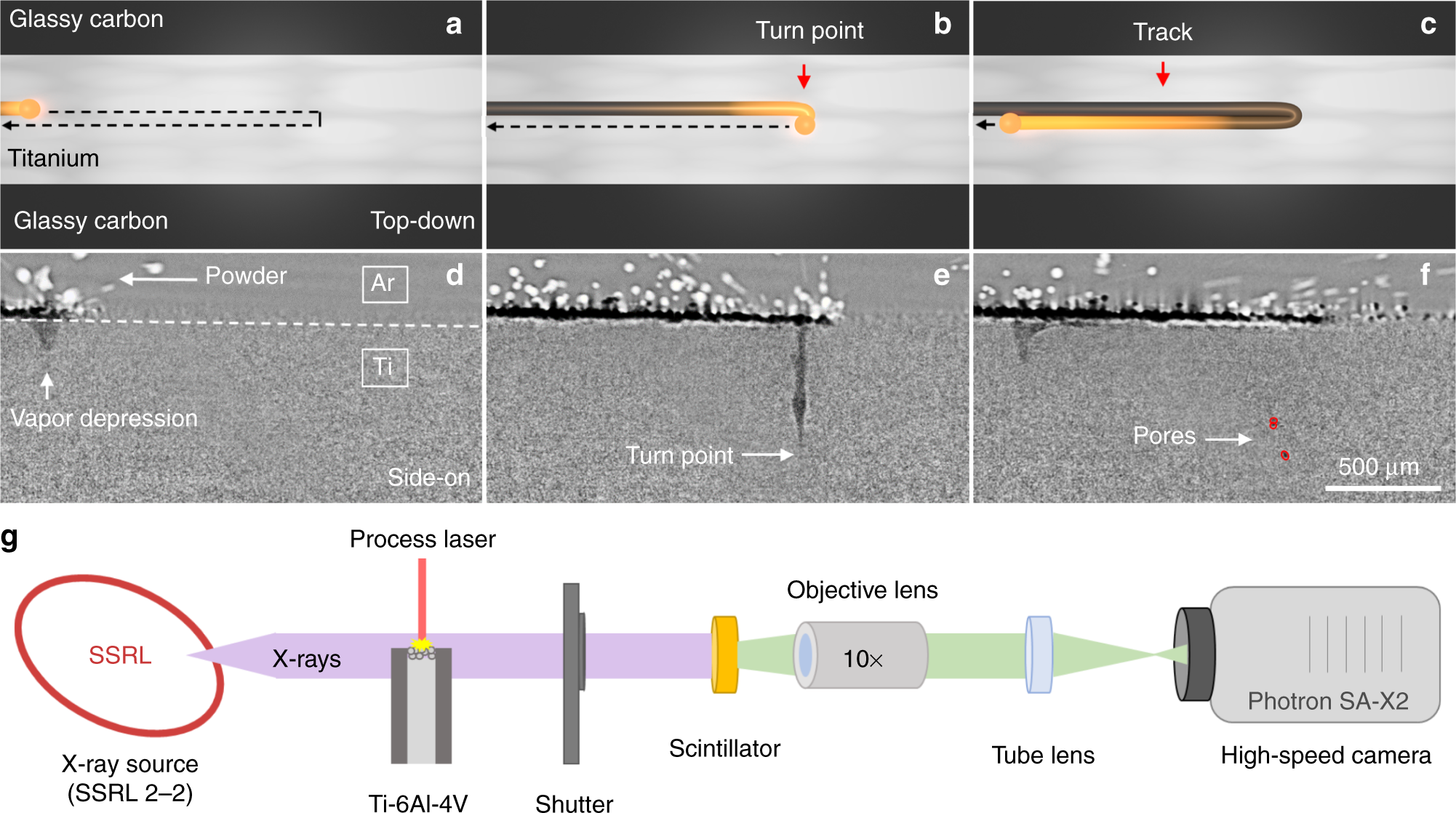

Dynamics of pore formation during laser powder bed fusion additive manufacturing | Nature Communications

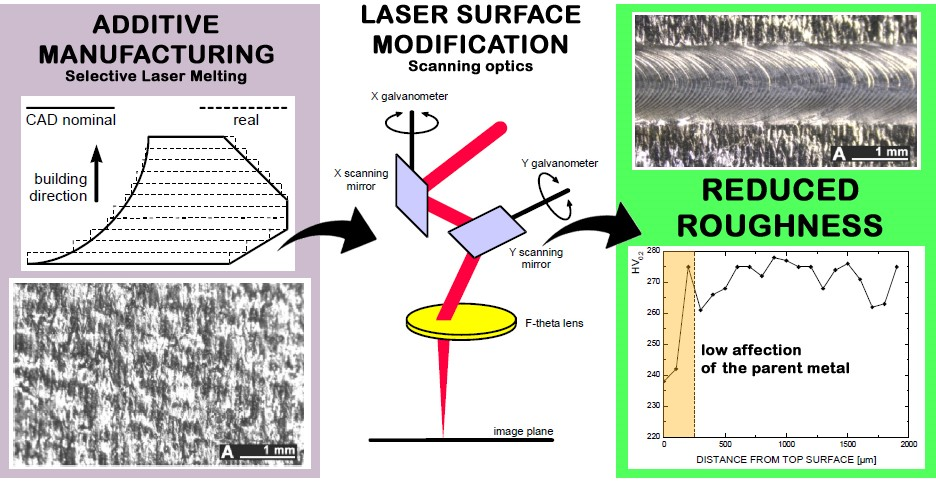

Materials | Free Full-Text | Reduction of Surface Roughness by Means of Laser Processing over Additive Manufacturing Metal Parts

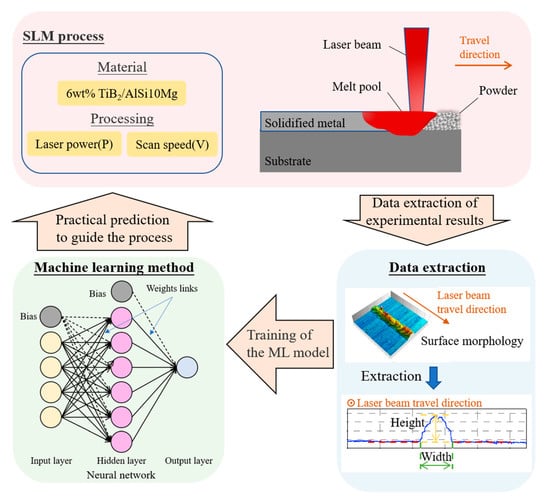

Materials | Free Full-Text | Predicting the Printability in Selective Laser Melting with a Supervised Machine Learning Method

Fatigue strength assessment of “as built” AlSi10Mg manufactured by SLM with different build orientations - ScienceDirect

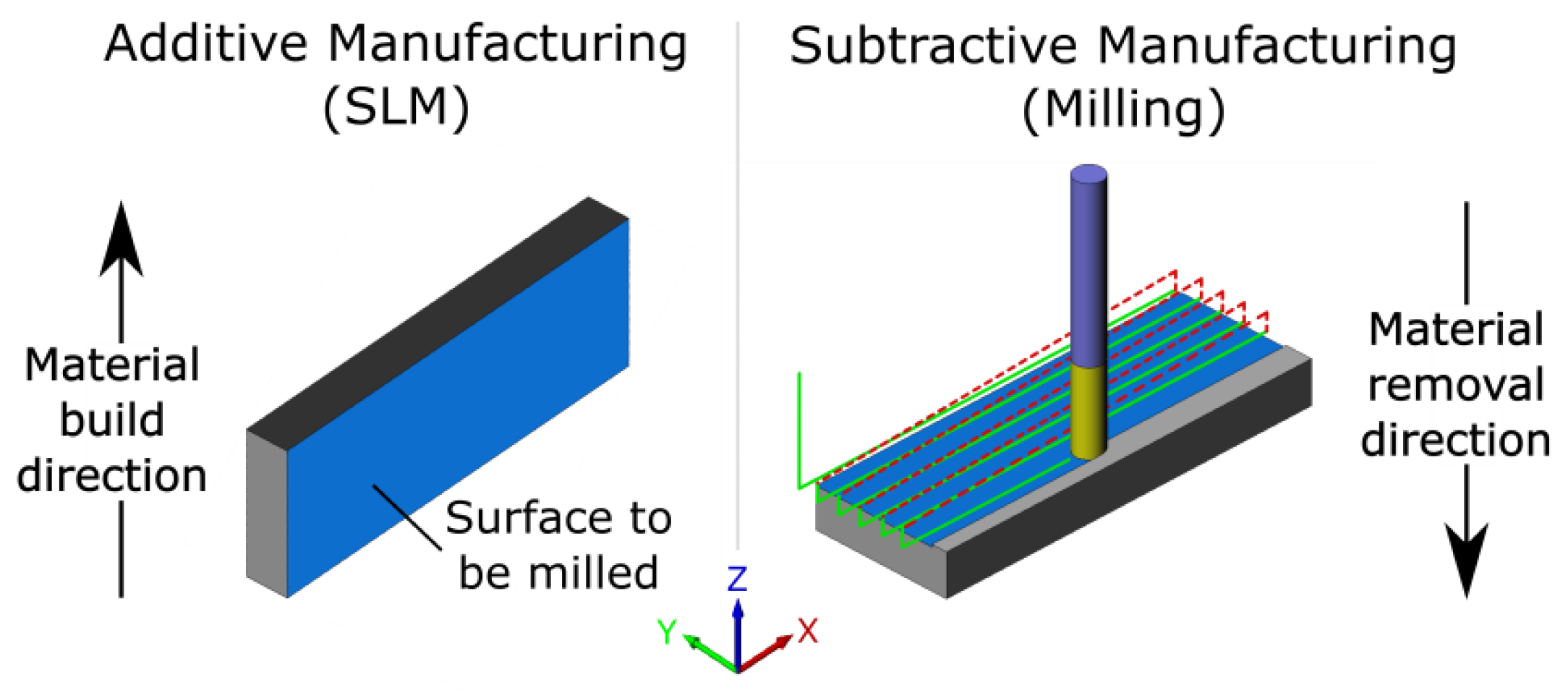

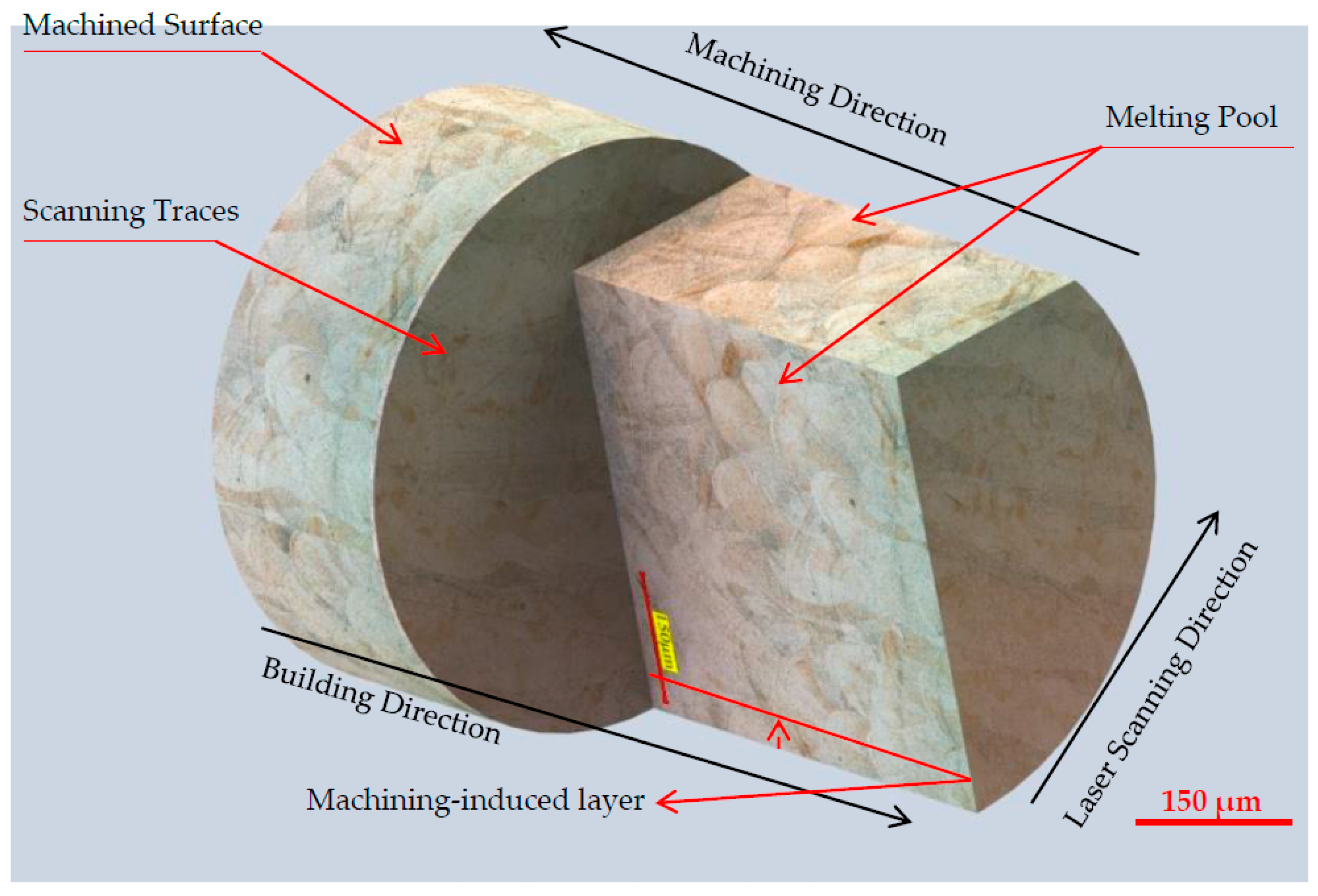

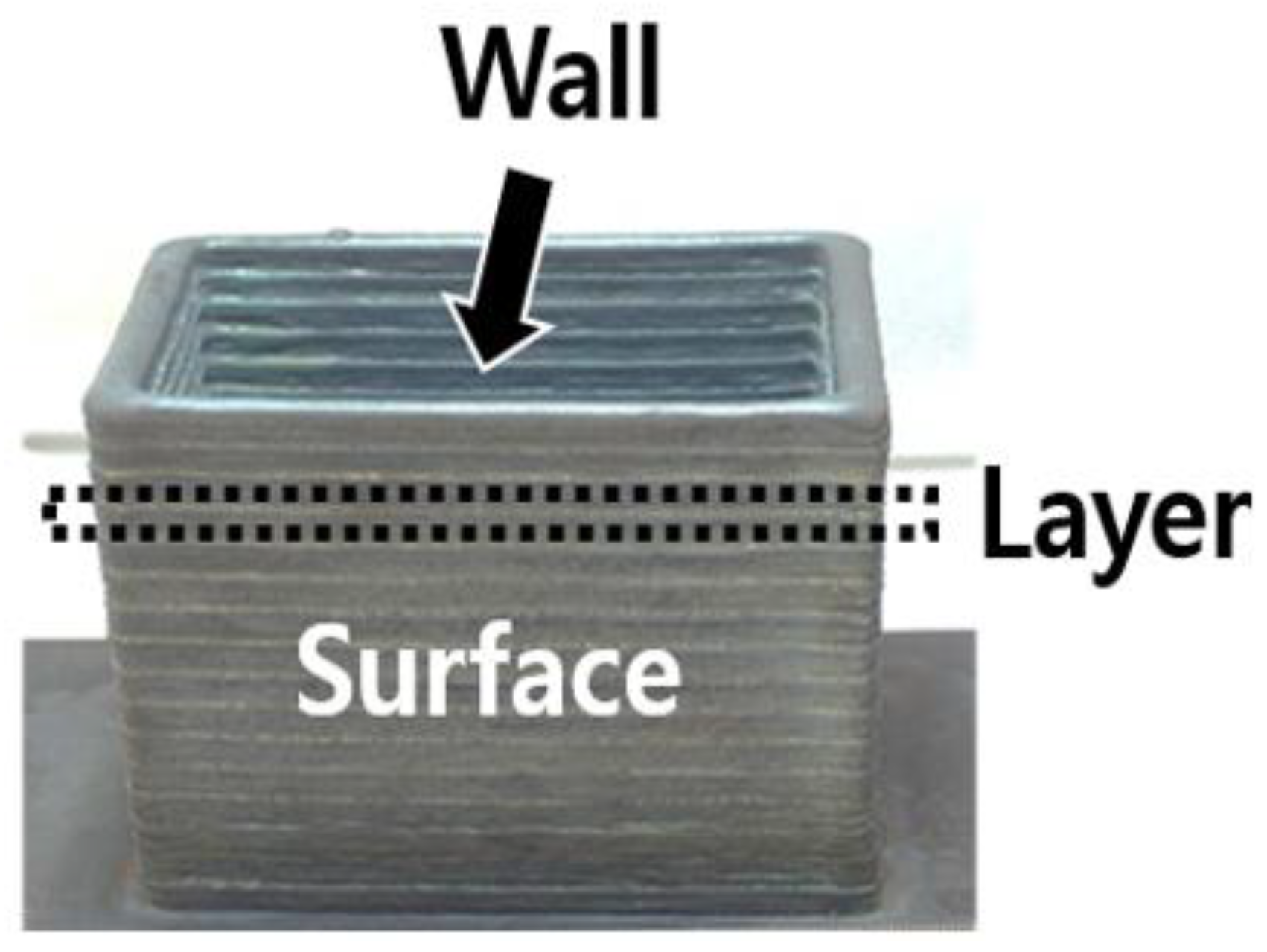

JMMP | Free Full-Text | Porosity, Surface Quality, Microhardness and Microstructure of Selective Laser Melted 316L Stainless Steel Resulting from Finish Machining

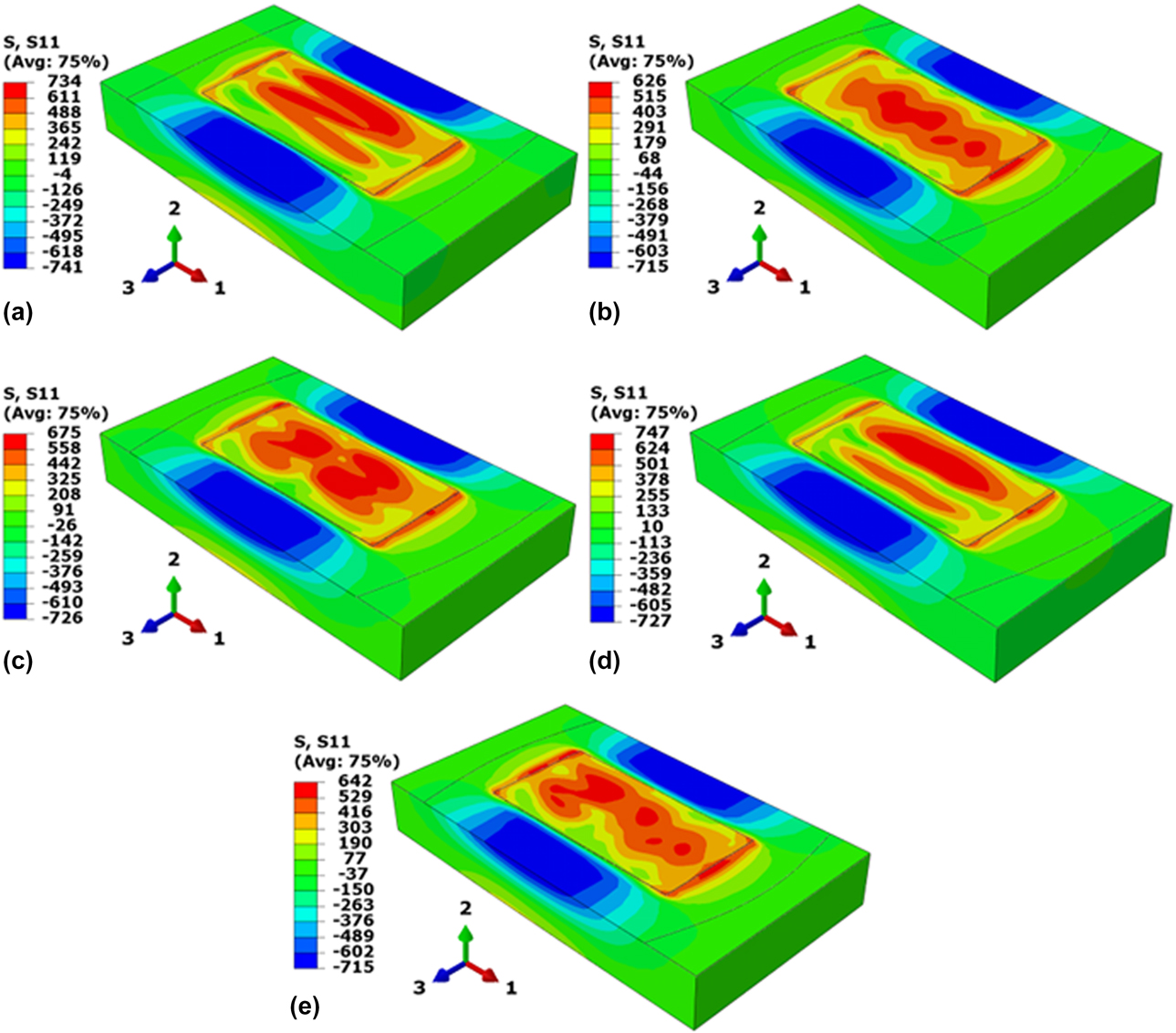

Understanding processing parameters affecting residual stress in selective laser melting of Inconel 718 through numerical modeling | Journal of Materials Research | Cambridge Core

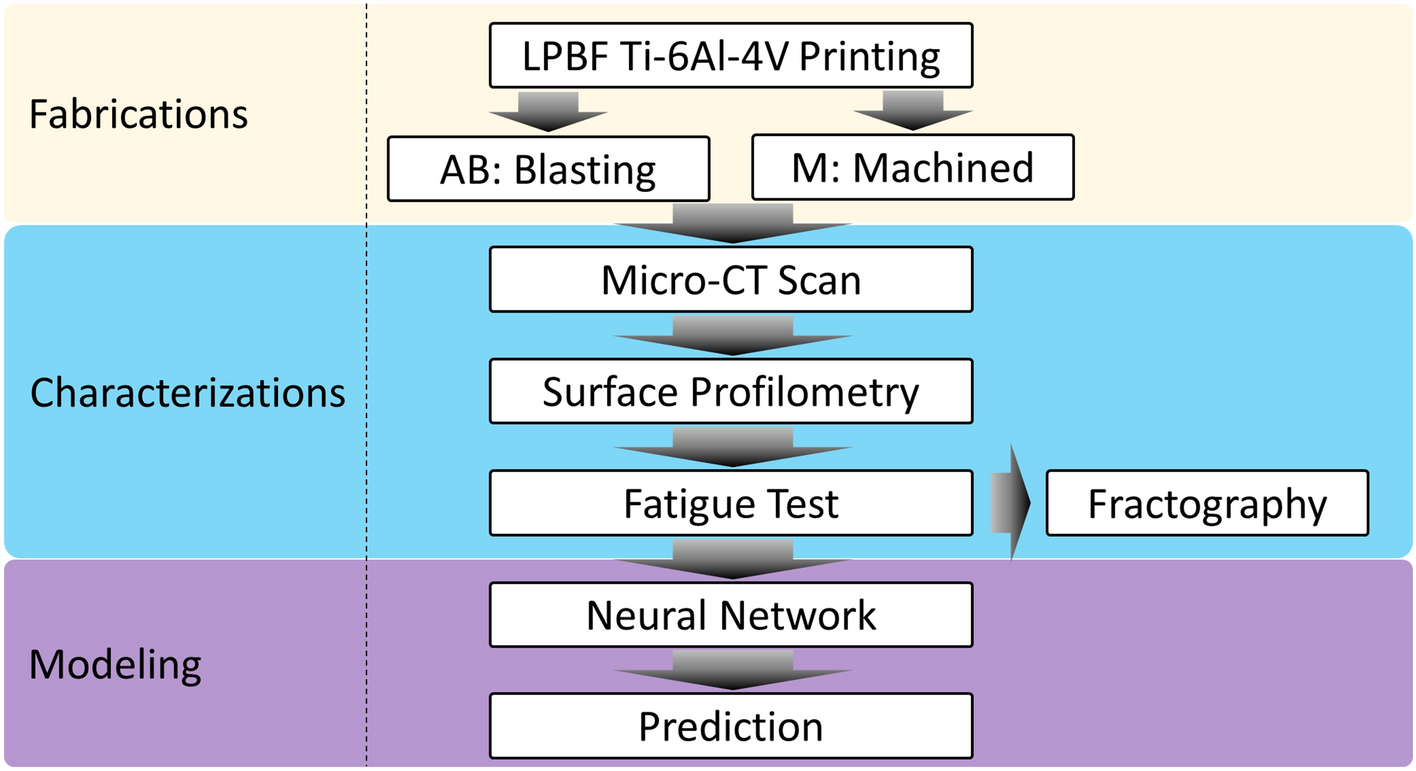

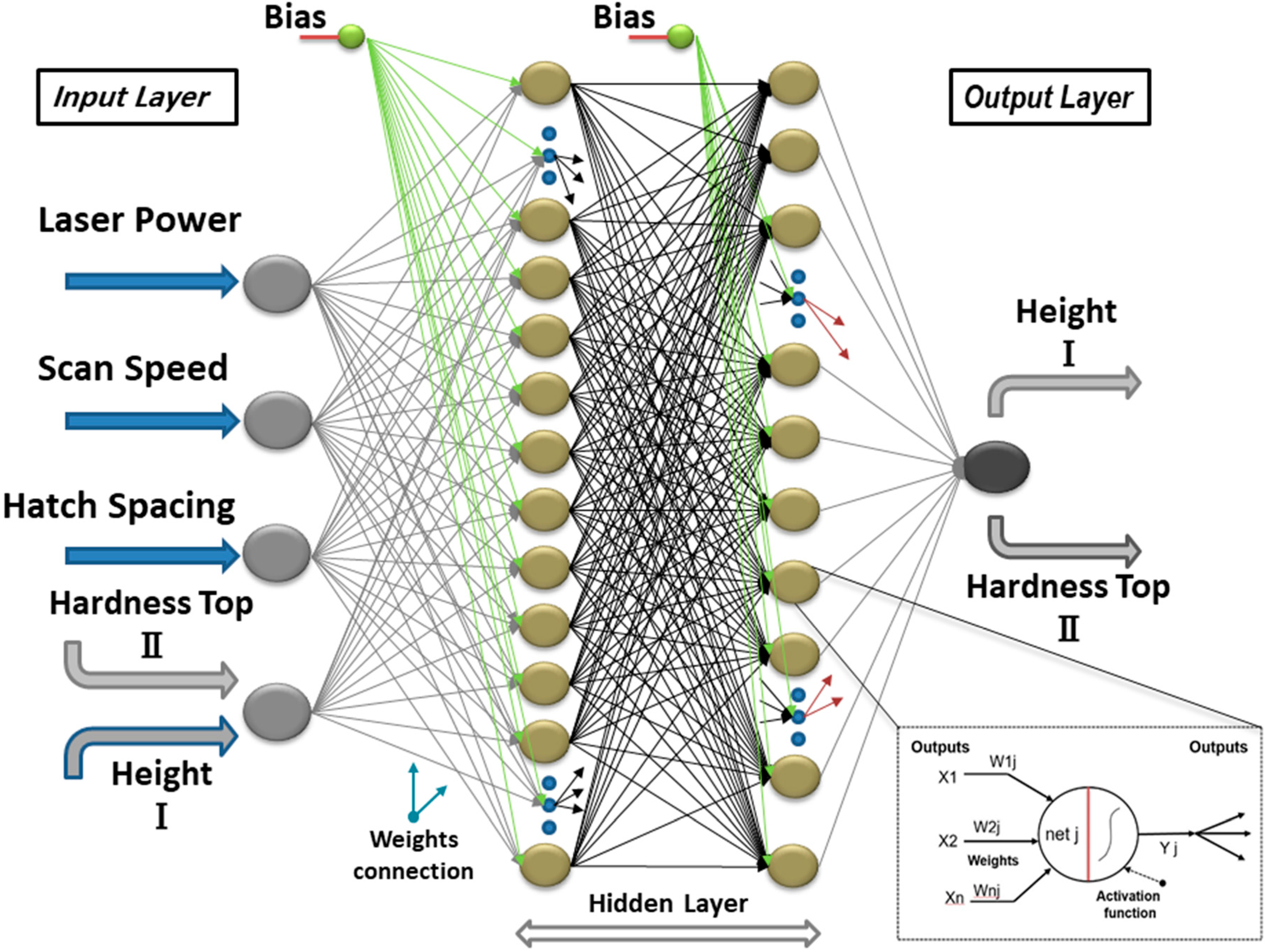

Impact of surface and pore characteristics on fatigue life of laser powder bed fusion Ti–6Al–4V alloy described by neural network models | Scientific Reports

Applied Sciences | Free Full-Text | A Prediction Model for Additive Manufacturing of Inconel 718 Superalloy

Sensors | Free Full-Text | Prediction of Metal Additively Manufactured Surface Roughness Using Deep Neural Network

Model of surface roughness and material removal using abrasive flow machining of selective laser melted channels | Emerald Insight

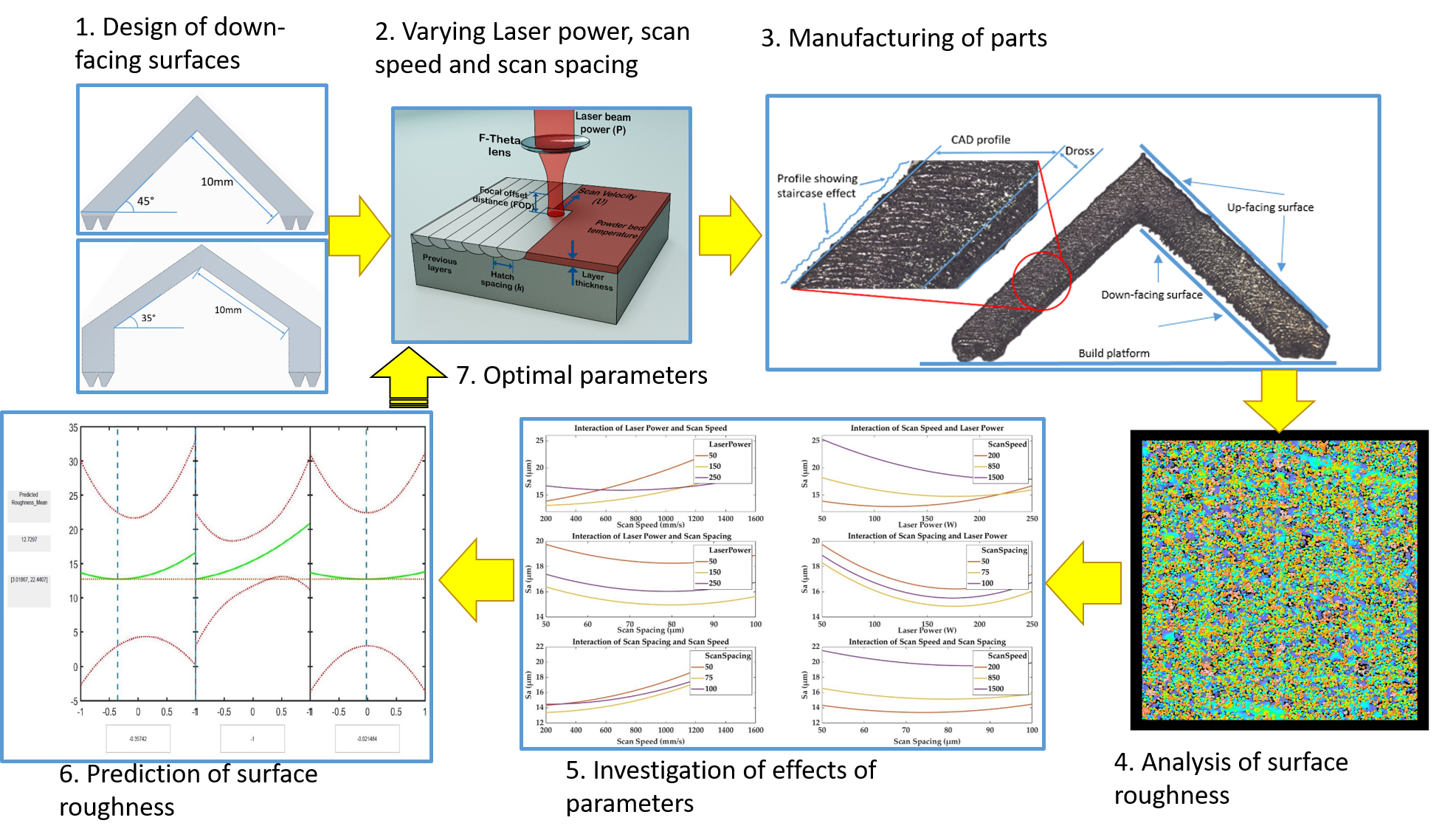

Applied Sciences | Free Full-Text | Effect of Process Parameters on the Generated Surface Roughness of Down-Facing Surfaces in Selective Laser Melting